Polytetrafluoroethylene (PTFE) is a carbon and fluorine polymer. This material has the most familiar name: Teflon.

Properties of PTFE include:

- Excellent mechanical properties (<1%)

- Chemical inertness corrosion resistance

- Heat resistance

- Lowest coefficients of friction

- Non stick properties(withstands continuous high temperatures of 500°f (260°c))

- Wear resistance

- High melting point

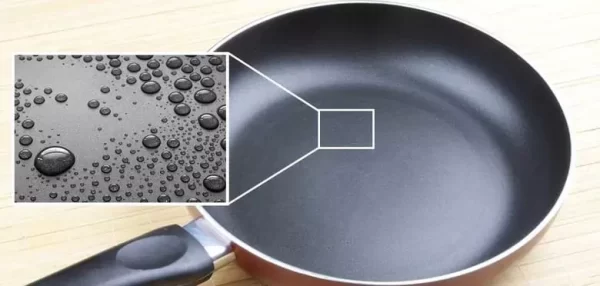

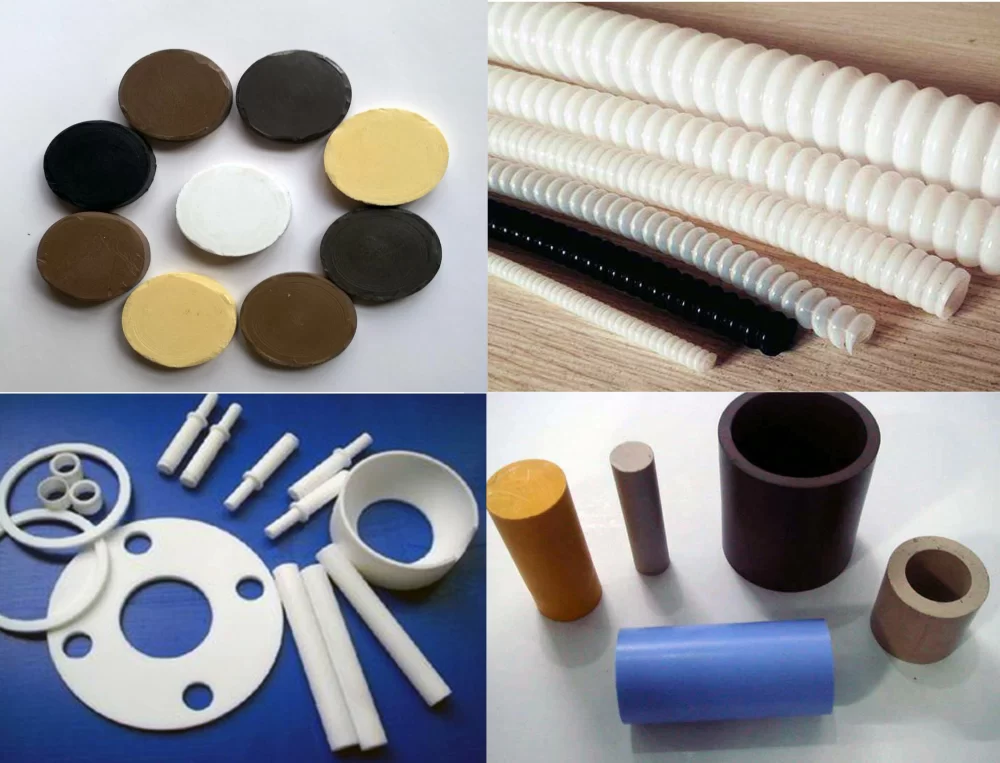

The excellent properties of PTFE give it a wide range of applications, and it is most commonly used as a non-stick coating for cookware. PTFE’s better wear resistance allows it to be combined with various materials through emulsion polymerization or suspension polymerization processing to form high thermal-resistant industrial products with excellent mechanical properties, such as wire insulation, food-grade conveyor belts, flexible non-stick fabrics, etc.

What Is PTFE?

Polytetrafluoroethylene was discovered in 1938. It was originally discovered by American chemist Roy J. Plunkett (1910–1994) when he was trying to make a new carbon and fluorine compound refrigerant. People at the time would not have thought of this ordinary product. Strange catalysts will affect every aspect of the world.

In 1941, DuPont obtained a patent for this product and registered a trademark under the name “Teflon” in 1944.

Nowadays, polytetrafluoroethylene has been widely used in many fields of production and life. In the catering industry, PTFE coated cookware is widely used; in the clothing industry, top cold-proof clothing from brands such as HELIKON and Carinthia all use PTFE as the coating or outer layer. , in order to achieve the ability to withstand the severe cold of -30°C; in the military field, PTFE materials with low loss, excellent dielectric properties, good consistency, stable chemical properties, and almost no moisture absorption are widely used in high radio frequency radar panels. In the medical field, PTFE materials are also widely used in artificial body parts.

What Does PTFE Stand For?

PTFE stands for polytetrafluoroethylene, the chemical term for the polymer (C2F4)n.

This material generally refers to any branded ptfe synthetic fluoropolymer. The main characteristics of polytetrafluoroethylene are as follows:

- Maximum operating temperature (°F /°C): 500/260

- Tensile Strength at Break (PSI): 4,000

- Dielectric constant (kV/mil): 3.7

- Proportion: 2.16

- Elongation at break: 350%

- Shore D Hardness: 54

The widely used ptfe polytetrafluoroethylene synthetic fluoropolymer with the above characteristics already has countless brands, the main brands are as follows:

- TEFLON®: Chemours

- FLUON®: AGC Ltd

- DYNEON®: 3M

- POLYFLON: Daikin Industrial Co., Ltd.

- ALGOFLON: Solvay Ltd.

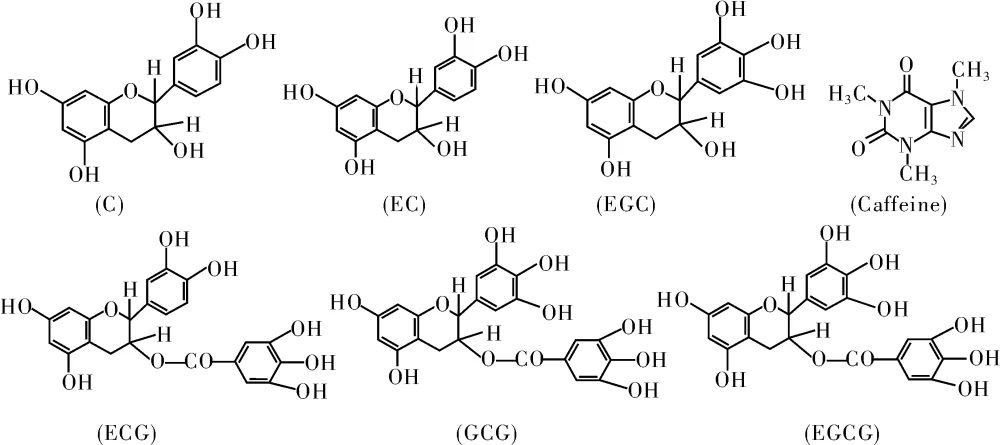

PTFE Chemical Structure

Polytetrafluoroethylene is a linear polymer composed of carbon (C) and fluorine (F) atoms, with the chemical formula (C2F4)n, where n is the number of monomer units.

The structure of PTFE can be expressed as: -CF2-CF2-CF2-CF2-

The long chain of PTFE molecules is made up of carbon atoms, each of which is linked to two fluorine atoms.

Fluorine atoms almost cover the surface of the carbon atoms of the spiral polymer chain. The carbon atoms form the main chain of the polymer chain. The fluorine atoms form a shield-like structure around the carbon atoms, which well protects the internal carbon atoms.

This unique arrangement of atoms gives PTFE its exceptional properties. This molecular structure contributes to PTFE’s unparalleled physical and chemical properties.

What Is The Teflon Material?

Teflon is a thermoplastic fluoropolymer, and Teflon acronym is PTFE (polytetrafluoroethylene).

Teflon is a trademark of Chemours, however, PTFE can also be purchased from companies other than Chemours. Teflon is a popular material due to its low friction, high temperature resistance, and chemical resistance.

Is Teflon PTFE

Of course, Teflon is a polymer material polymerized from tetrafluoroethylene and is a type of perfluorinated material. Its chemical name is polytetrafluoroethylene (PTFE).

Teflon chemical structure is very unique. The molecular structure is that F (fluorine atoms) replaces all H (hydrogen atoms) on the C chain. At the same time, because the radius of the fluorine atom is much larger than the radius of the carbon atom, the repulsion between atoms is very large, so it will not Like hydrogen atoms, they can be arranged in a plane, so the fluorine atoms almost spiral up to wrap the carbon atoms, so that the outside world can only come into contact with the relatively inert fluorine atoms.

With a strong fluorine atom barrier, the Teflon polymer structure is relatively stable compared to other materials.

Teflon Properties

PTFE is a polymer polymerized from tetrafluoroethylene monomer. It is a transparent or opaque wax similar to PE. Its density is 2.2g/cm3 and its water absorption rate is less than 0.01%.

The chemical structure of PTFE polymer is similar to that of PE, except that all hydrogen atoms in polyethylene are replaced by fluorine atoms. Due to the high bond energy and stable performance of the C-F bond, it has excellent chemical corrosion resistance and can withstand all strong acids (including aqua regia) except molten alkali metals, oxidizing media, and sodium hydroxide above 300°C. As well as the effects of strong oxidants, reducing agents and various organic solvents.

The F atom in the PTFE molecule is symmetrical, and the two elements in the C-F bond are covalently bonded. There are no free electrons in the molecule, making the entire molecule neutral. Therefore, it has excellent dielectric properties, and its electrical insulation is not affected by The influence of environment and frequency.

Teflon Physical Properties

Its volume resistivity is greater than 1017, its dielectric loss is small, its breakdown voltage is high, its arc resistance is good, and it can work in an electrical environment of 250°C. Because there are no hydrogen bonds in the PTFE molecular structure, the structure is symmetrical, so its crystallization The degree of crystallization is very high (generally the crystallinity is 55%~75%, sometimes as high as 94%), which makes PTFE extremely heat-resistant. Its melting temperature is 324C, its decomposition temperature is 415°C, and its maximum use temperature is 250°C. It is brittle The temperature is -190°C, and the heat distortion temperature (under 0.46MPa conditions) is 120C.

Teflon material has good mechanical properties. Its tensile strength is 21~28MPa, bending strength is 11~14MPa, elongation is 250%~300%, and its dynamic and static friction coefficients against steel are both 0.04, which is better than nylon, polyformaldehyde, and polyethylene. The coefficient of friction of cool plastics is small.

Pure PTFE has low strength, poor wear resistance and poor creep resistance. It is usually necessary to add some inorganic particles to the PTFE polymer, such as graphite, disulfide group, aluminum oxide, glass fiber, carbon fiber, etc. to improve its mechanical properties. , and can also be expanded by cooperating with other polymers such as polyphenylase (PHB), polyphenylene sulfide (PFS), polyethylene glycol (PEEK), polyethylene/propylene copolymer (PFEP), etc. its damping temperature range, improving its resistance to variability

How Is Teflon Made

The manufacturing process uses chloroform as raw material, uses anhydrous hydrofluoric acid to fluorinate chloroform, the reaction temperature is above 65ºC, uses antimony pentachloride as a catalyst, and finally uses thermal cracking to produce tetrafluoroethylene.

Aokai is produced using suspension polymerization or emulsion polymerization.

- Preparation of monomer tetrafluoroethylene

Industrially, chloroform is used as raw material, anhydrous hydrofluoric acid is used to fluorinate chloroform, the reaction temperature is above 65ºC, antimony pentachloride is used as a catalyst, and finally tetrafluoroethylene is produced by thermal cracking. Tetrafluoroethylene can also be produced by reacting zinc with tetrafluorodichloroethane at high temperatures.

- Preparation of polytetrafluoroethylene

In an enamel or stainless steel polymerization kettle, water is used as the medium, potassium persulfate is used as the initiator, perfluorocarboxylic acid ammonium salt is used as the dispersant, fluorocarbon is used as the stabilizer, and tetrafluoroethylene is redox polymerized to obtain fine powdered polyethylene. Tetrafluoroethylene.

Add various additives to the reaction kettle, and the tetrafluoroethylene monomer enters the polymerization kettle in the gas phase. Adjust the temperature in the kettle to 25°C, then add a certain amount of activator (sodium metabisulfite) to initiate polymerization through a redox system. During the polymerization process, monomers are continuously added, and the polymerization pressure is maintained at 0.49~0.78MPa. The dispersion obtained after polymerization is diluted to a certain concentration with water, and the temperature is adjusted to 15~20ºC. After aggregation with mechanical stirring, it is washed with water and dried, that is, This product is obtained as fine granular resin.

Is Teflon Safe?

Teflon coating itself is safe: Teflon material itself is non-toxic, will not decompose, and will not cause health hazards. This is probably because its molecular structure is basically insoluble in real chemicals, let alone digested and absorbed by the human body.

What Is PTFE Used For?

The unique properties of PTFE make it widely used in industrial and marine operations such as chemical industry, petroleum, textile, food, papermaking, medicine, electronics and machinery.

- Application of polytetrafluoroethylene (PTFE) in anti-corrosion properties:

Due to the defects in corrosion resistance of rubber, glass, metal alloys and other materials, it is difficult to meet the harsh environment where temperature, pressure and chemical media coexist, and the resulting losses are quite alarming. While PTFE material has excellent corrosion resistance, polytetrafluoroethylene uses the main corrosion-resistant materials in petroleum, chemical, textile and other industries.

Specific applications include: delivery pipes, exhaust pipes, steam pipes for transporting corrosive gases, high-pressure oil pipes for rolling mills, high, medium and low-pressure pipes for aircraft hydraulic systems and cold press systems, distillation towers, heat exchangers, kettles, towers and tanks. The performance of chemical equipment seals such as linings and valves has a great impact on the efficiency and performance of the entire machine and equipment. PTFE material has the characteristics of corrosion resistance, aging resistance, low friction coefficient and non-stickiness, wide temperature range, and good elasticity, making it very suitable for manufacturing seals with high corrosion resistance requirements and operating temperatures above 100°. Such as seals for grooved flanges of machines, heat exchangers, high-pressure vessels, large-diameter vessels, valves, and pumps, seals for glass reaction pots, flat flanges, large-diameter flanges, shafts, piston rods, valve rods, Worm gear pumps, tie rod seals, etc.

2.The low friction performance of polytetrafluoroethylene (PTFE) is used in load applications.

The friction parts of some equipment are not suitable for lubrication, such as in situations where lubricating grease will be dissolved by solvents and become ineffective, or in papermaking, pharmaceuticals, food, textiles, etc. Products in the industrial field need to avoid lubricating oil contamination, which makes filled PTFE materials the most ideal material for oil-free lubrication (direct load bearing) of mechanical equipment parts. This is because the friction coefficient of this material is the lowest among known solid materials. Its Specific uses include bearings for chemical equipment, papermaking machinery, and agricultural machinery, as piston rings, machine tool guide rails, and guide rings. They are widely used in civil construction projects as support slides for bridges, tunnel steel structure roof trusses, large chemical pipelines, and storage tanks. Blocks, as well as used as bridge supports and bridge swivels, etc.

3.Applications of polytetrafluoroethylene (PTFE) in electronic and electrical applications.

The inherent low loss and small dielectric constant of PTFE materials enable it to be made into enameled wires for use in micro motors, thermocouples, control devices, etc., PTFE electrical insulation film It is an ideal insulating material for manufacturing capacitors, radio insulating liners, insulated cables, motors and transformers. It is also one of the indispensable materials for industrial electronic components such as aerospace and aerospace. The use of fluorine plastic films has high permeability to oxygen and high permeability to water vapor. This selective permeability of small permeability can be used to manufacture oxygen sensors. The characteristics of fluoroplastics that cause polar charge deviation under high temperature and high pressure can be used to manufacture microphones, speakers, parts on robots, etc., and their low refraction can be used. The characteristics of high efficiency can make optical fibers.

4.Application of polytetrafluoroethylene (PTFE) in medical medicine.

The expanded PTFE material is purely inert and has very strong biological adaptability. It will not cause rejection by the body and has no physiological side effects on the human body. It can be sterilized by any method. Its microporous structure allows for use in a variety of rehabilitation solutions, including artificial blood vessels and patches for soft tissue regeneration and surgical sutures for vascular, cardiac, general and orthopedic surgeries.

5.Application of anti-stick properties of polytetrafluoroethylene (PTFE).

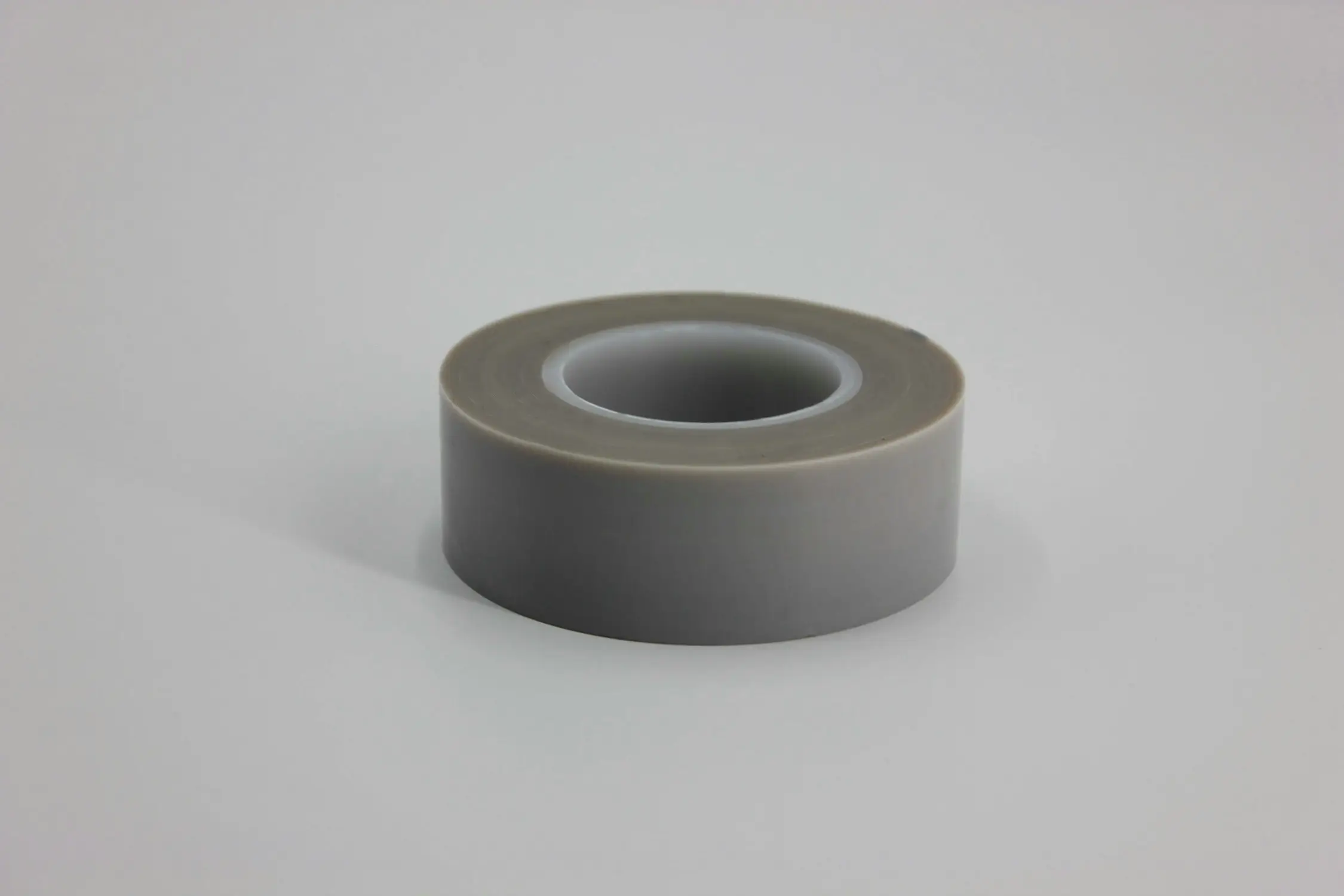

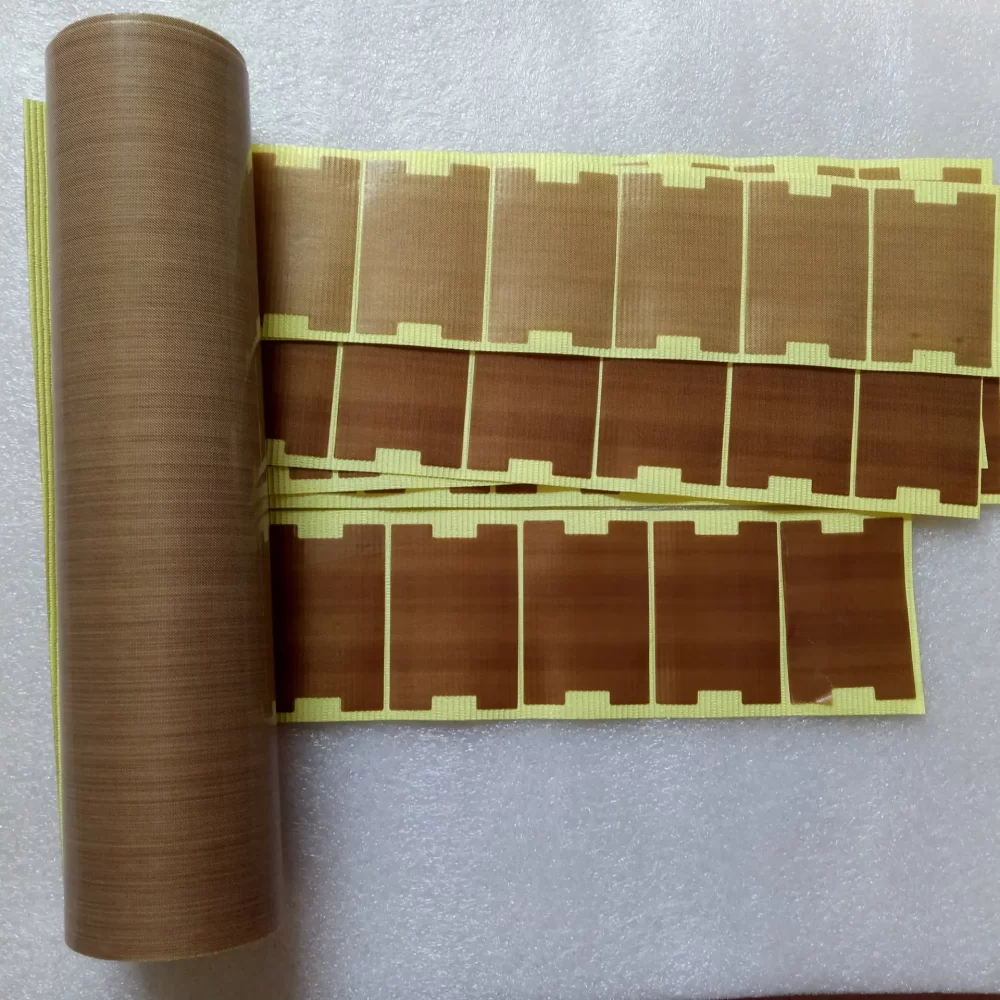

PTFE Coated fabric

PTFE material has the smallest surface tension among solid materials and does not adhere to any substance. It also has the characteristics of high and low temperature resistance and chemical inertness, making it suitable for applications such as manufacturing. Non-stick pans are widely used in anti-stick applications. The anti-adhesive process mainly includes two types: installing the PTFE sheet on the substrate and placing the PTFE coating or varnish composited with glass on the substrate through heat shrinkage.

Although PTFE materials still have the problem of high difficulty in welding, with the advancement of technology, new synthesis methods will soon solve the pain points of PTFE and apply PTFE to a wider range of fields.